- Home

- Products

- Turn-key plants

- Tube cutting machine

- Tube Sealing Machine

- Seam Spot Welding machine

- Longitudinal/Transverse seam Welding Machine

- Tubular Heating Plates

- Bathroom radiators

- Plasma Cover Welding

- MF Projection Welding

- Convector press I

- Convector press II

- Production line

- Test bath

- Transport route

- Laminate press

- Service

- The Company

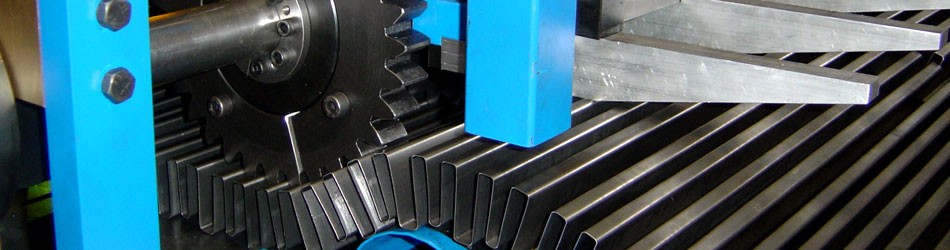

High-power laminate press with direct connection to the welding line

The machine consists of a winch with a coil loading block, a sheet alignment device, an inlet table with roller feed, sheet draw-in rollers, sheet lubrication and longitudinal roller shear, an eccentric press with a planetary gear and a pressing force of 200 tons with our patent step tool. After this, there is a swivel outlet table (about 2.5 m long), the hydraulic cutting shear and a complex laminated sheet transport route up to the welding line. In order to achieve good synchronisation between the convector units and plates, our convector press is combined directly with the half-shell press. The automatically controlled convector press works with the number of strokes being between 45 and 70 strokes per minute, and produces four shafts per stroke with our patented step tool. The maximum production is about 12 m per minute with 2-line production.